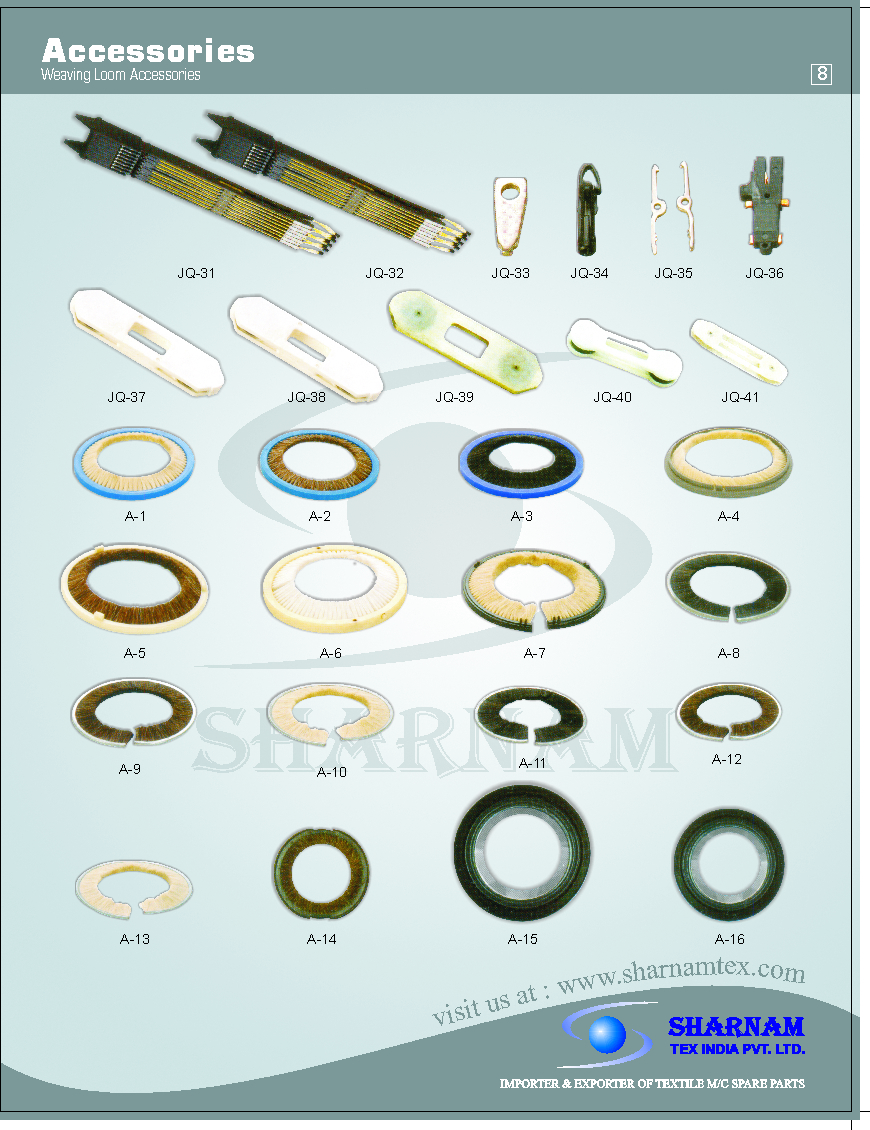

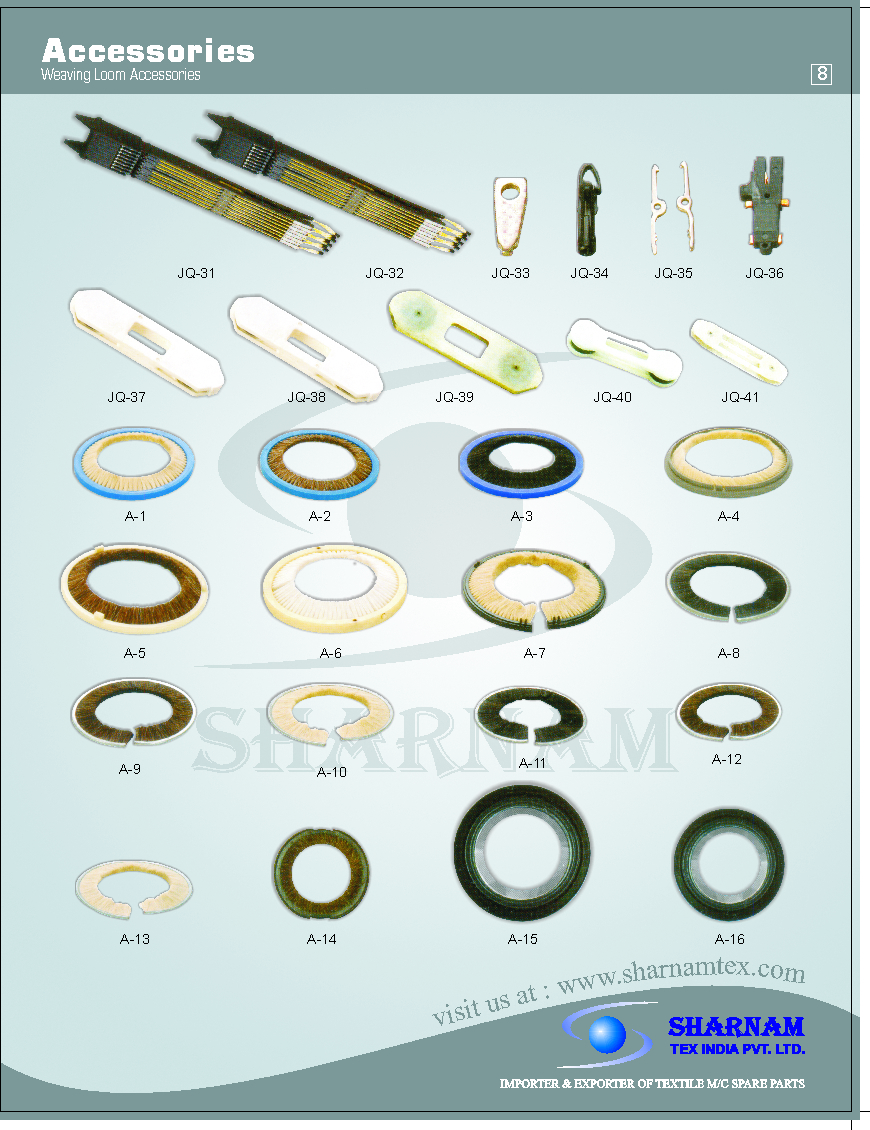

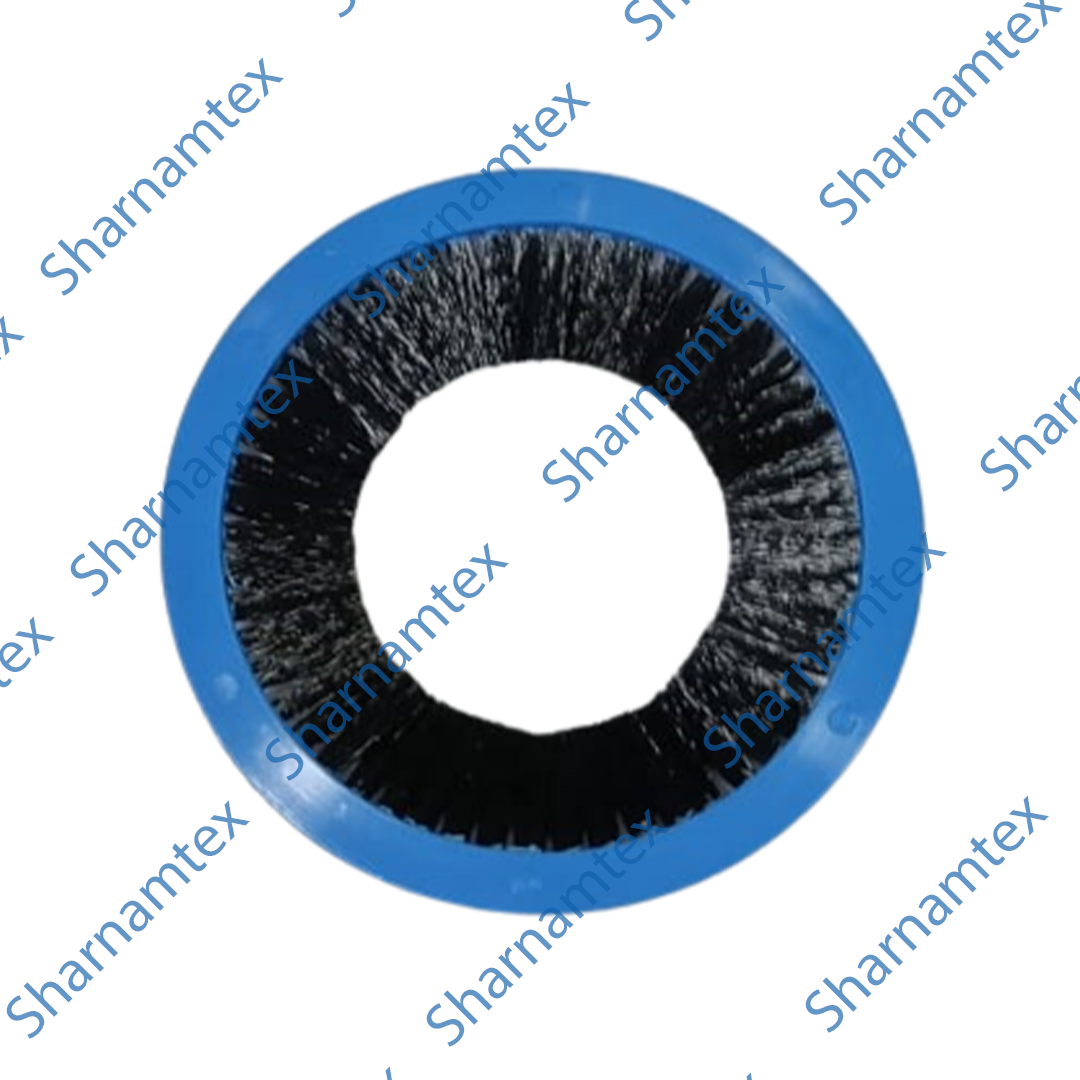

About WEFT FEEDER BRUSH FOR WEAVING

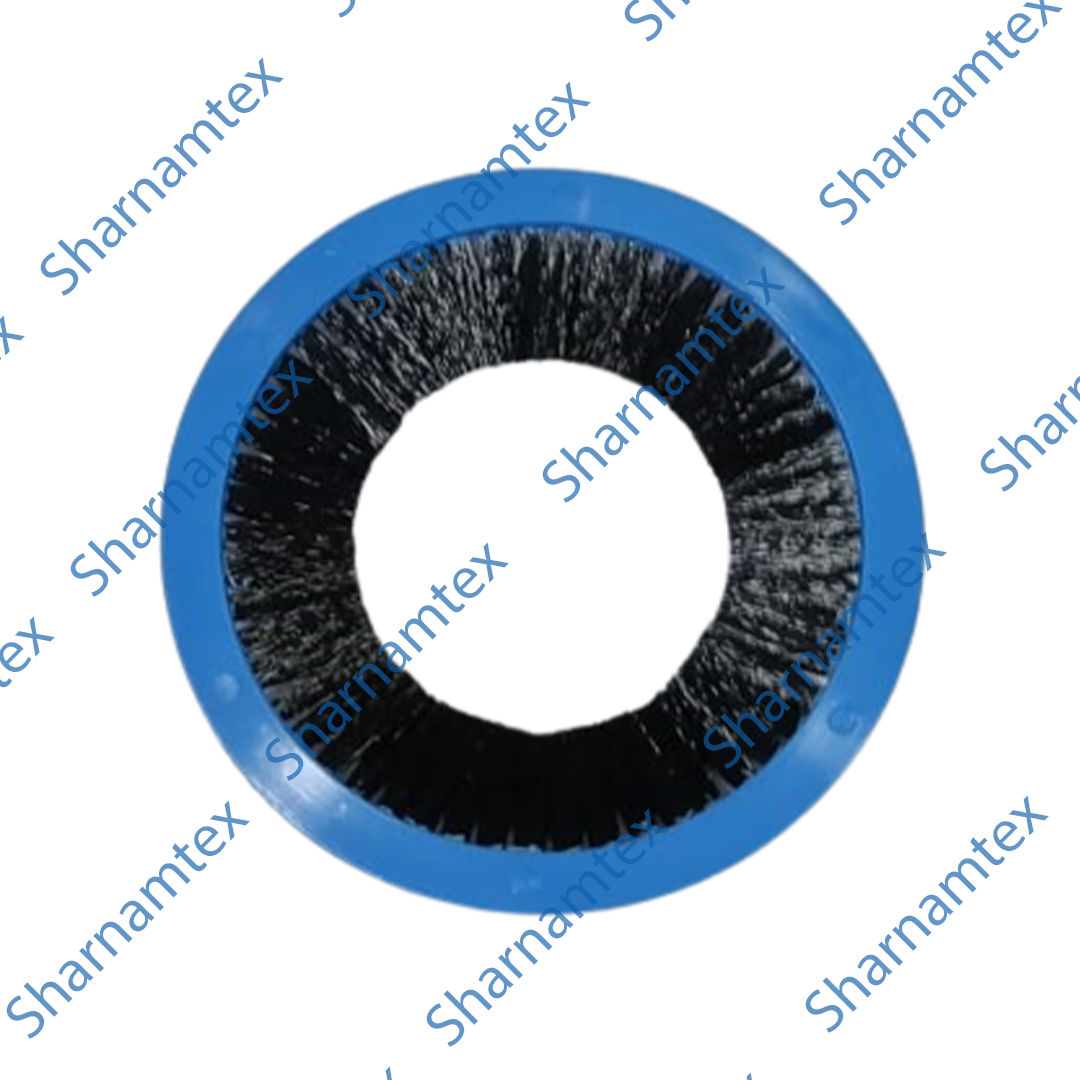

BRUSH FOR ACCUMULATOR ALL TYPES LGL BRUSH, NORMAL BRUSH, LOCK TYPE BRUSH, CUT TYPE BRUSH HAIR DIMENSION 15MM & 25MM

SOFT HAIR, MEDIUM HAIR, HARD HAIR

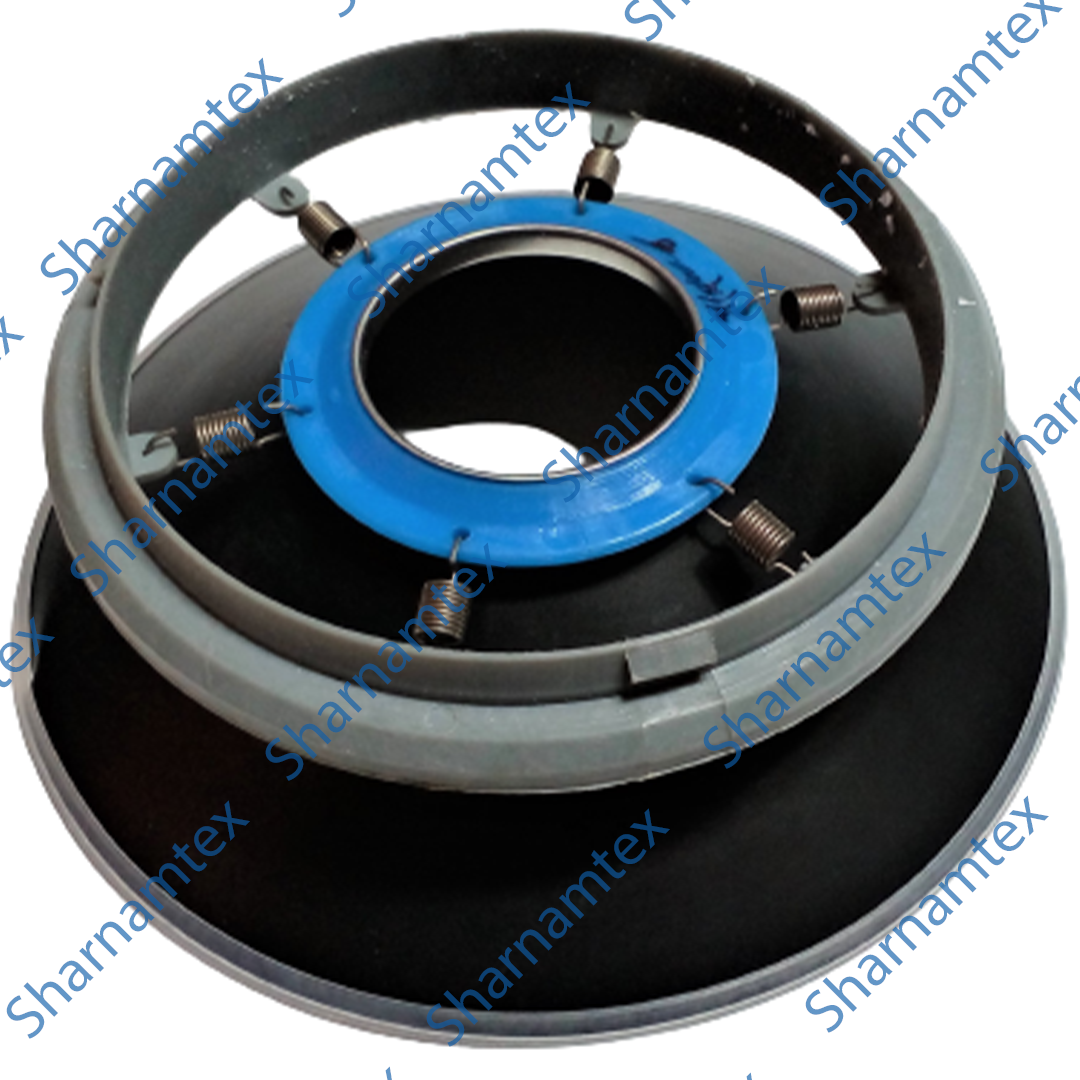

Textile Machinery Accumulator play an important role in the weaving machines where the weft is unwound overhead from the cone and is subjected to abrupt accelerations due to the drawing-off tension exerted by the insertion element. Textile Machinery Accumulator is demanded for its quality and performance as tested prior to dispatch.

Superior Durability and CompatibilityEngineered with robust materials, the Weft Feeder Brush resists abrasion and chemicals, supporting seamless operation in industrial weaving. Its compatibility with various weft feeder brands and adaptable sizing ensure it meets diverse machine specifications, effectively reducing downtime and maintenance frequency.

Optimized for Industrial EfficiencyWith a medium hardness and fine-bristle thread configuration, this brush delivers low-noise, high-speed performance. It maintains consistent yarn tension and offers long wear life, making it invaluable in continuous textile production. Direct mounting and customizable options maximize utility and convenience for operators.

FAQs of WEFT FEEDER BRUSH FOR WEAVING:

Q: How do I clean the Weft Feeder Brush for Weaving?

A: The recommended cleaning method is dry brush cleaning. Gently remove accumulated lint and debris using a soft, dry brush to maintain optimal performance and avoid damaging the fine bristles.

Q: What makes this brush suitable for various weft feeder brands?

A: The brush is designed with variable diameter and customizable dimensions, making it compatible with different weft feeders across multiple weaving machine brands. This flexible design ensures proper fit and efficient operation.

Q: When should I replace the weft feeder brush?

A: It is advisable to follow your machines upkeep cycle for brush replacement. Regular inspection for wear and tension consistency will help determine the optimal replacement interval and maintain textile quality.

Q: Where can this brush be used?

A: This weft feeder brush is intended for industrial weaving machines, supporting both manual and automated setups. It is particularly useful in textile mills and factories utilizing high-speed, continuous weaving processes.

Q: What benefits does this brush provide during continuous operation?

A: The brush is engineered for high tensile strength, optimized capacity, and longevityensuring uniform yarn tension and low noise across sustained industrial production, contributing to consistent fabric quality and reduced maintenance disruptions.

Q: How does mounting work for this brush?

A: The brush utilizes a direct mount system, allowing for straightforward installation onto compatible weft feeders without the need for extensive modifications. This results in minimal machine downtime when performing replacements or maintenance.